{{ $t('shop.all.spaetbestellservice.hinweis') }}

Skupina artiklov

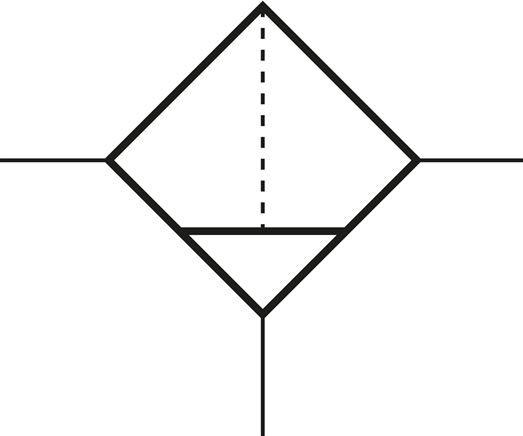

Fini filter - Multifix, do 4200 l/min*

Materials:

Body: die-cast zinc Z410 (model series 4 & 5: aluminium), seals: NBR, condensate container: die-cast zinc (model series 5: aluminium) or polycarbonate

Temperature range:

-10 do +60 °C

Media:

Compressed air, neutral gases

ATEX:

Operating material without its own potential source of ignition in accordance with Directive 2014/34/EU (not model series 4)

Advantages:

•Easy assembly of individual components using coupling kits within a model series and thread size.

Note about semi-automatic condensate drain:

As soon as the input pressure drops below the min. input pressure, the drain valve opens automatically. By screwing the drain screw tight, the semi-automatic opening of the drain valve can be prevented.

Application:

Microfilters are used where high requirements are required for the purity of the compressed air requirements. Finest particle (> 0,01 µm) and oil mist is separated here. We recommend the upstream connection of a prefilter to increase the service life.

Dust removal:

> 0,01 µm (99,999 %)

Residual oil content:

0.01 mg/m³ (Class 1 according to DIN ISO 8573-1)

Input pressure:

1.5 - 16 bar, with metal tank max. 20 bar** (series 0: when using coupling packet max. 12 bar)

Optional:

Model series 0 (only type FX 018), 1 and 2: Protective cage -S, model series 2 and 4: Metal bowl with inspection tube -M, model series 1, 2 and 4: automatic drain -AM, automatic discharge closed when not pressurised (0 to 16 bar) -AMNC

*at inlet pressure 6 bar and 0.1 bar pressure loss, **Metal tank with automatic draining AM/AMNC: max. 16 bar

{{ $t('shop.all.dokumente') }}:

Catalogue page Atlas 9 (Page 586) atlas9_seiten/586.pdf

Dokumentacijo doku/wartungsgeraete_multifix.pdf

Dokumentacijo: Decision aid for selection of air units doku/entscheidungshilfe_wartungsgeraete.pdf

Dokumentacijo doku/wartungsgeraete_multifix.pdf

Dokumentacijo: Decision aid for selection of air units doku/entscheidungshilfe_wartungsgeraete.pdf

{{ $t('shop.display.artikelgruppe.mehr_informationen') }}

{{ $t('shop.display.artikelgruppe.weniger_informationen') }}

{{ $t('shop.display.artikelgruppe.filtern') }}

Fini filter - Multifix, do 4200 l/min*:

{{ $t('shop.all.artikelgruppe_n_von_m_artikeln', { anzahlArtikelAngezeigt: anzahlArtikelAngezeigt, anzahlArtikelGesamt: anzahlArtikelGesamt} ) }} {{ $t('shop.all.unverbindliche_richtwerte') }}

Možnosti plačila:

{{ $t('shop.all.wochenendversand.hinweis') }}

Pojavila se je napaka!

Pojavila se je napaka, znova naložite stran in poskusite znova.